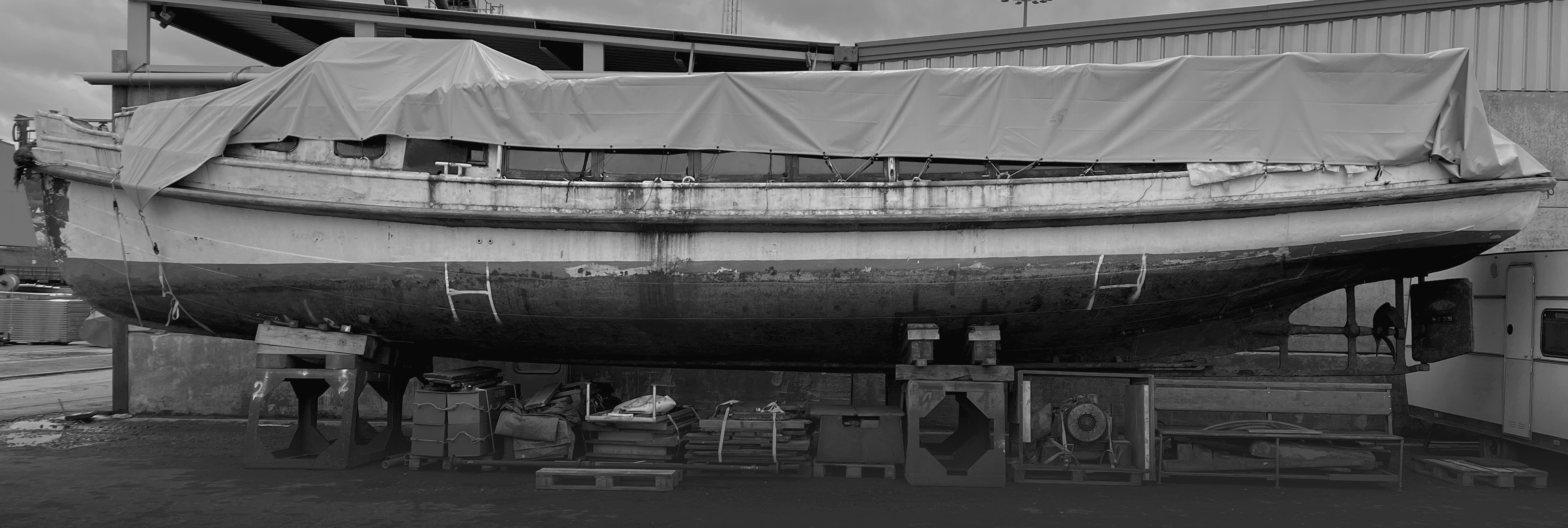

Transforming the UHU II into Liminaris is an ongoing and meticulous process. This document will be regularly updated with our plans for the design and reconstruction, technical equipment, artistic content, and the partners collaborating with us to achieve this vision. According to the examination report by the Schiffsuntersuchungskommission BG Verkehr Regionalabteilung Hamburg, the inner floor of the ship was sealed, allowing only an exterior examination of the hull. Concrete had been poured into the bottom of the hull to balance it, leading to the recommendation of repair by doubling, which was carried out at the stern. The prescribed minimum thickness of the steel plates is 3.1 mm for the chine and 3 mm for the rest of the hull. We have emptied and cleaned the inside of the ship, removing the engine, exhaust, and cooling systems. Additionally, the concrete was removed, the inside of the hull was cleaned, and loose paint and rust were eradicated to fully assess the ship's condition and determine the necessary repairs. Due to health concerns and the COVID-19 crisis, the ship had been largely unused and neglected by its previous owners. We performed an initial ultrasound measurement of the plate thickness, revealing that while most of the hull is in fairly good shape, there are areas of serious rust damage primarily caused by rainwater leaking through the roof into the sealed floor. The ship was originally constructed with plate thicknesses averaging 4.5 to 5.5 mm, riveted to the frames. To restore the hull, we will cut out the damaged plates and weld in new ones. Despite the commission's recommended minimum thickness, we have decided to use a minimum of 4 mm thickness for greater durability.The next steps include a second ultrasound measurement of the hull, followed by a crucial LiDAR 3D scan. This scan will produce a precise 3D model of the entire hull, serving as a major reference for the restoration process.

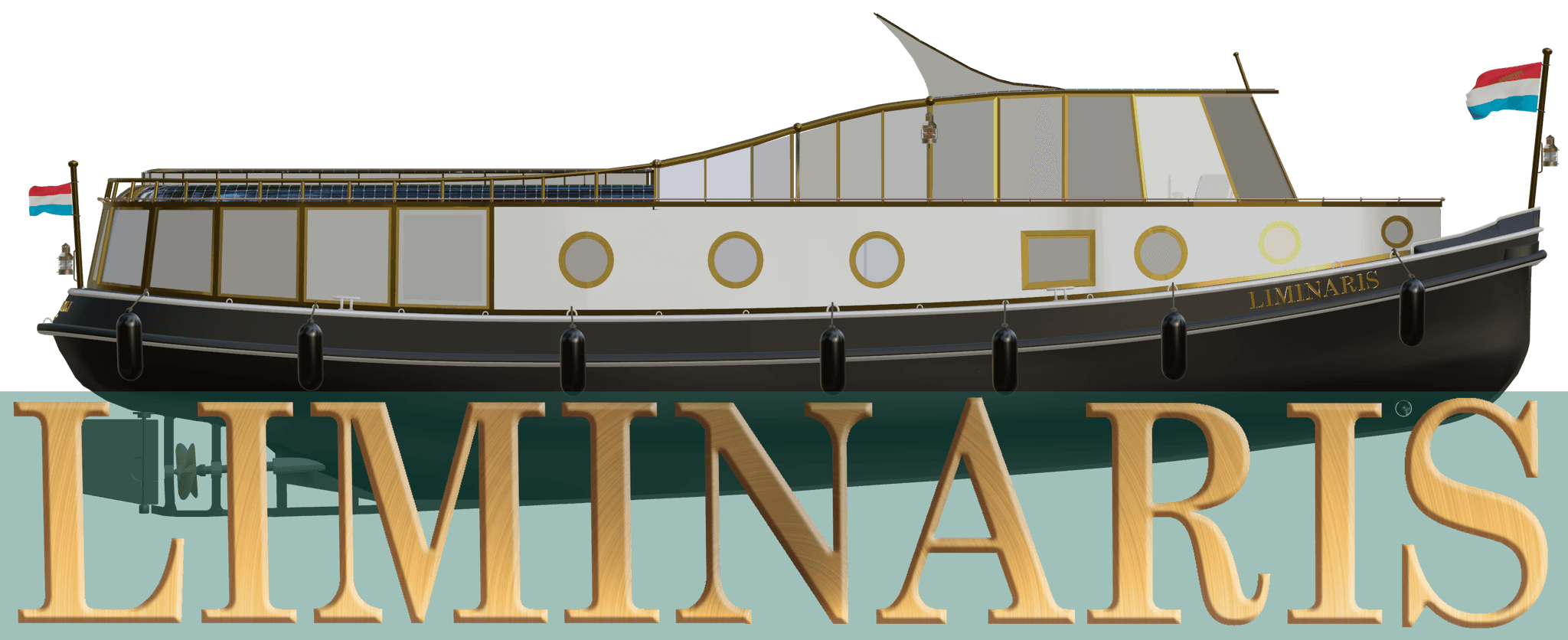

Transforming the UHU II into Liminaris is an ongoing and meticulous process. This document will be regularly updated with our plans for the design and reconstruction, technical equipment, artistic content, and the partners collaborating with us to achieve this vision.

According to the examination report by the Schiffsuntersuchungskommission BG Verkehr Regionalabteilung Hamburg, the inner floor of the ship was sealed, allowing only an exterior examination of the hull. Concrete had been poured into the bottom of the hull to balance it, leading to the recommendation of repair by doubling, which was carried out at the stern. The prescribed minimum thickness of the steel plates is 3.1 mm for the chine and 3 mm for the rest of the hull. We have emptied and cleaned the inside of the ship, removing the engine, exhaust, and cooling systems. Additionally, the concrete was removed, the inside of the hull was cleaned, and loose paint and rust were eradicated to fully assess the ship's condition and determine the necessary repairs. Due to health concerns and the COVID-19 crisis, the ship had been largely unused and neglected by its previous owners. We performed an initial ultrasound measurement of the plate thickness, revealing that while most of the hull is in fairly good shape, there are areas of serious rust damage primarily caused by rainwater leaking through the roof into the sealed floor. The ship was originally constructed with plate thicknesses averaging 4.5 to 5.5 mm, riveted to the frames. To restore the hull, we will cut out the damaged plates and weld in new ones. Despite the commission's recommended minimum thickness, we have decided to use a minimum of 4 mm thickness for greater durability.The next steps include a second ultrasound measurement of the hull, followed by a crucial LiDAR 3D scan. This scan will produce a precise 3D model of the entire hull, serving as a major reference for the restoration process.